UVLED FAQ

发布时间:2022-03-03 15:53

来源:萤光创新

How does UVLED dissipate heat

1. Heat generation must be controlled during use. The chip temperature in the drive is affected by the thermal resistance of the circuit board and the configuration density of the LED. Therefore, in the circuit board design, pay attention to dispersing the heat and prevent the LED junction temperature (TJ) from exceeding the absolute maximum rating.

2. The driving current of this product should be determined according to the ambient temperature (TA), and the heat generated should be dissipated.

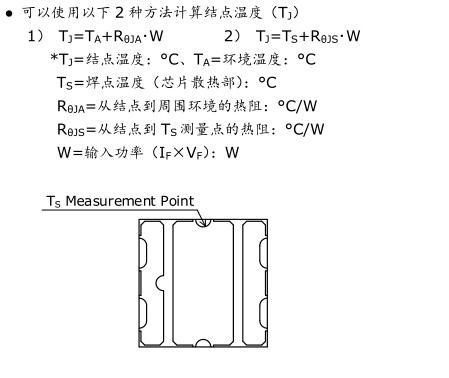

3. The following two methods can be used to calculate the junction temperature (TJ)

Precautions in anti-static

1. This product is sensitive to static electricity and surge voltage, and the chip may be damaged under the impact of static electricity and surge voltage, which affects the reliability of this product. Therefore, the following anti-static countermeasures should be used in operation.

① Use anti-static bracelets, conductive clothing, conductive shoes, conductive floors, etc. to remove charges;

① Use anti-static bracelets, conductive clothing, conductive shoes, conductive floors, etc. to remove charges;

② Ground the devices and tools in the operation area to remove the charge;

③ Workbench and storage shelves made of conductive materials.

2. Properly ground all tools, equipment and devices that need to be grounded in the operation area. In addition, the installed modules or products of this product also need to implement surge voltage countermeasures.

3. If glass or plastic insulators are used in tools and devices, the following anti-static countermeasures should be used.

① Conducting electricity with conductive materials;

② Humidification to prevent static electricity;

③ Neutralize the charge using an ion generator.

4. In the characteristic inspection after installing the product into the module, finally check whether there is electrostatic damage. Static damage can be detected by positive voltage inspection under low current (≤ 1mA).

5. If the initial voltage of the product is abnormal, it will decrease.

Criteria for nonconformity determination: (VF < 2.0V at if = 0.5mA)

How to clean UVLED?

1. It is better not to clean this product. If it cannot be avoided, it must be confirmed in advance that the cleaning agent will not cause adverse effects on the external package and glass lens.

2. It is better not to use ultrasonic cleaning for this product, because the output power of ultrasonic cleaning and the installation method of circuit board may have adverse effects on LED. If ultrasonic cleaning cannot be avoided, it must be confirmed in advance that it will not affect the actual use.

Qingdao fluorescent Innovation Technology Co., Ltd. has a professional postdoctoral team, focusing on the research of ultraviolet sterilization application. After years of deep cultivation in the ultraviolet industry, the company has obtained a number of national invention and utility model patents. At present, a number of sterilization module products have been put into the market. For more details, please visit the company's website at www.qdyingguang.com Com contact the company for the official account of WeChat.

Keywords: 220nm, 230nm, 235nm, 240nm, 245nm, 250nm, 255nm, 260nm, 265nm, 270nm, 275nm, 280nm, 285nm, 290nm, 295nm, 300nm, 305nm, 310nm, 315nm, 320nm, 330nm, 340nm, 365nm, 395nm, 405nm, to39, uvworks, uvworks, UVC works, UVC eors, UV LED, UVA led, UVB led, UVC led, deep UV LED, UV sterilization Ultraviolet disinfection, ultraviolet sterilization, ultraviolet disinfection scheme, sterilization module, water purifier sterilization, terminal sterilization faucet, static water sterilization component, flowing water sterilization component, ultraviolet sterilization water purifier, sterilization faucet, toothbrush sterilization, water cup sterilization, surface sterilization, water sterilization, air sterilization and phototherapy